Supply Chain Issues in the Cannabis Industry: 3 Factors and What You Can Do to Protect Yourself

Previously Posted on Omega Equipment & Supply Blog

Before we discuss the supply chain issues in the cannabis industry, we want to start on a more positive note. The cannabis industry has had some pieces of good news lately. The global pandemic is showing signs of improvement which is leading to more business opportunities. There are also promising signs on the federal legislative front. And as new states come online with both medical and recreational marijuana programs, there will be a concurrent need to ramp up the infrastructure of the cannabis industry to meet the increased demand in these states.

But supply chain issues in the cannabis industry may throw a wrench in some plans. Essential equipment may take longer to acquire and prices may rise for a number of reasons. Fortunately, with some planning and guidance, operators in the cannabis space can avoid painful and often expensive delays.

Let’s first look at some of the root causes of the supply chain issues in the cannabis industry to better understand how we got here, how long this situation may last, and how we can minimize the impact of these issues on cannabis operators.

Raw Materials Shortages

This is the most basic of the supply chain issues in the cannabis industry. Raw materials are scarce in a number of areas. We can’t review every type of shortage but there are two that have great potential to affect cannabis operators. The first has to do with the most common metal frequently used for both building construction and in the equipment used in the cannabis industry: Steel. The second concerns petroleum products and all of the derivative products that rely on petroleum as a key component.

Other raw materials and key components of note include a shortage of nickel which is used in semiconductors and batteries, as well as being a key component in stainless steel. Nitrile and some related rubber products from China and Malaysia are also in short supply (more on that below).

Steel

Steel is a key component of equipment found in every aspect of the cannabis industry. It doesn’t matter if it’s cultivation, extraction, manufacturing of cannabis products, or even items for retail & dispensaries. Steel is also a key component for the construction of new buildings. Steel is everywhere.

But, unfortunately, steel is in short supply and prices are surging.

“Our members have been reporting that they have never seen such chaos in the steel market,” said Paul Nathanson, executive director at Coalition of American Metal Manufacturers and Users.

Understanding why we are experiencing shortages is a bit more complicated. While these economic conditions are a boon for steel manufacturers, those companies that need steel to produce their products are facing longer lead times and skyrocketing prices.

Part of this stems from tariffs on steel imposed by former president Trump beginning in 2018. This was done to protect the US steel industry. But even with the 25% tariff on imported steel, US customers would be better off paying the tariff and having the steel imported. Domestic steel prices have risen sharply and are nearly 70% above the global market price. This includes being almost double the price of Chinese steel imports.

Compounding the problem is that steel supplies remain low abroad as demand continues to rise. Add in some of the logistical problems we will discuss below and you have a recipe for rising costs and extended lead times for delivery.

Petroleum Products

Petroleum products (i.e., oil-based materials) are found in just about all products in some form or fashion. But as you have probably seen at the gas pump, oil prices have been on the rise. Part of this is simply a seasonal effect as refineries shift production from different grades of products. But some of the issues have to do with the difficult winter that the US experienced that was then capped off by a bad run of nasty Spring weather in the Gulf of Mexico and Southern United States which caused disruptions in production and refineries along the Gulf of Mexico.

And as we slowly re-emerge from COVID-19 quarantine protocols, pent-up demand for travel in the US will continue to drive demand upward. So, with reduced supply and increasing demand, we find ourselves again in a position of rising costs and lengthening lead times.

Logistical Issues

Cargo ships unloading containers at port. Back ups in all phases can cause weeks/months of delays.

The US imports many of the products used by the cannabis industry. That means that they often have to be shipped from overseas, received in US ports, and then distributed from there. As you probably already know, in the US, we import much more than we export. That is, we have more goods and materials coming into the US than we are sending to other countries.

Most of this international commerce involves container ships. These containers are then loaded onto railcars or trucks to be delivered across the country. Once all those individual containers have been dispersed across the nation, how do they get back to where they are needed (i.e., back in China where they can be used to ship more goods)?

We wish that the solution was easy: We just pack the empty containers with goods that the US is exporting to Asia. But, alas, that isn’t what happens. The answer is complicated. Although it is expensive, it has become more profitable for shipping companies to ship empty containers on a return voyage. This has caused another issue in creating container shortages for US agricultural exporters.

According to Progressive Farmer, “It’s a no-brainer for the shippers because a cargo of Chinese electronics or clothes going to the U.S. could pay as much as $8,000 per container, while an export of agricultural goods leaving the U.S. might pay $300 to $1,000 per container.”

Adding Insult to Injury

One of the biggest news stories of March 2021 was the case of a cargo ship blocking the Suez canal for nearly a week. Ironically, it was estimated that 420 ships were blocked from using the canal during this time which led to a major disruption of global trade. While this extreme incident grabbed the headlines, there has been congestion at major shipping ports in the US for nearly the entire duration of the global pandemic. And the situation isn’t likely to improve.

“This is a warning about how vulnerable our supply chains are and how the just-in-time inventory techniques that have been so popular have to be rethought,” said William Lee, chief economist at the Milken Institute.

Traffic jams at major ports and truck driver shortages are adding to the supply chain challenges.

And it isn’t just ships that are causing delays. There is a shortage of truck drivers as well. In 2020, the trucking industry recorded a record shortfall in the number of truck drivers required to meet demand. Better technology aimed at monitoring the driving hours of long-haul truckers is to blame for some of the issues. In years past, truckers could “bend the rules” to get shipments delivered faster. But with new electronic monitoring, the extra capacity that might have been gained by driving more hours than legally permissible has virtually disappeared. Without truck drivers to deliver them, these containers are often stuck in a logistical traffic jam that can take weeks or months to resolve.

Legalization Drives Demand

As more states open up their legal cannabis markets, cannabis operators will need to increase their production to meet demand.

In just the last year, we have seen a flurry of states adopting new medical and recreational marijuana legislation. Arizona, Virginia, New Jersey, New Mexico, and New York have all taken steps to open up their cannabis markets. And cannabis operators are preparing to ramp up to meet this expected increase in demand.

This means that the most common and popular pieces of equipment and supplies are also becoming hot commodities. Existing facilities are expanding and new facilities are being planned to meet the new demand.

This trend is true for all phases of the cannabis industry. Cultivators are trying to increase their output of biomass. Extraction specialists and manufacturers of cannabis products are ramping up production. Dispensaries are gearing up for increased traffic and demand by increasing their staff and trying to ensure that they will have sufficient products to meet consumer demand.

This trend will continue for the next several years as new states come online both with medical and recreational marijuana programs. So while some of the other factors driving supply chain issues may abate, consumer demand will continue to increase. And this will likely mean that there will be some shortages or delays for specific products or raw materials.

The Best Defense is Good Planning

Your supply chain partner can help you plan ahead to ensure product availability and save you money.

There is a saying in the cannabis industry: “However much money you think it will take to start your cannabis business, double it. And then double it again.“

This isn’t exactly true with regard to lead times for the delivery of equipment & supplies. But the sentiment still holds. You need to plan farther in advance than you probably think.

Planning doesn’t just involve deciding on what to purchase. It also involves contingency planning. What happens if the items you need are late? Or worse, what if they are unavailable altogether? Working with multiple vendors to coordinate deliveries can be challenging. First, you should identify items that are on the critical path for your project.

For example, if racking or lighting ballasts need to be installed before work on the rest of the project can continue, then these items are on your critical path. If you do not have these items, work cannot continue. You could be wasting money as employees and contractors are stuck waiting on your items to be delivered.

Some key points to remember:

Start planning earlier then you think you need to.

Identify items that are in your project’s critical path.

Build in contingencies into your schedule, just in case.

Buy Ahead

This may be difficult for some cannabis operators to swallow. Budgets are often tight. And financing is still difficult to come by at best. So buying supplies before you need them may be challenging for some cannabis operators. But understanding where the pinch points are on your key items and then buying ahead can help in two ways:

Buy ahead to ensure product availability when you need it.

Buy ahead to save money on products whose prices are going to increase as shortages worsen.

The airline industry does something like this with fuel purchases. They buy “futures” on fuel that allows them to purchase a set amount at an agreed-upon price in the future, regardless of what the current market rate may be.

While it isn’t exactly the same in the cannabis industry, you can use the same mindset to keep production steady and even increase profitability if material prices do continue to rise.

Forecast Your Usage

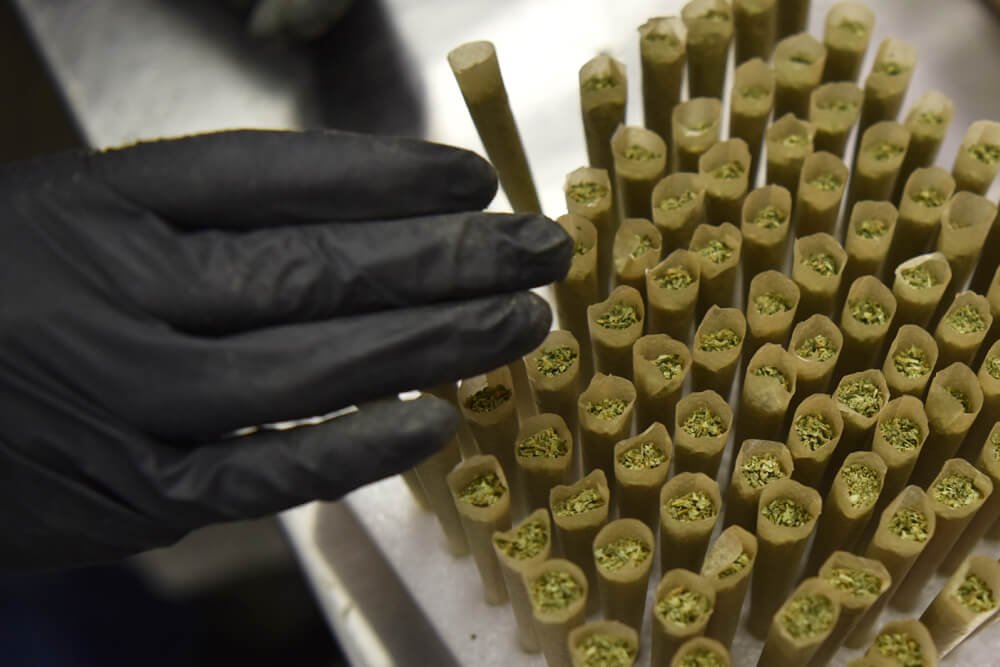

Nitrile gloves will continue to be in short supply & prices will continue to rise. Buying now for future use could save you money.

This strategy works best on items where you can forecast your usage rates. Nitrile gloves are a great example of this phenomenon.

Nearly all cannabis operators use disposable gloves in some form or fashion. Nitrile gloves are popular for their durability and chemical resistance. However, nitrile itself has become in short supply around the world. This shortage is projected to continue over the next year. And as a result, prices continue to increase.

So if you are able to stock up on nitrile gloves now, you can be sure that you have them available for your critical processes. And you can save money by buying them more cheaply now than buying them later at a higher price.

[Side note: As a contingency plan, you might investigate whether a vinyl/nitrile blend glove would work for your processes. While they are not as durable and do not stand up to chemicals as well, they can be an alternative for processes that do not require the rigors of a full nitrile glove. Plus, they are less expensive than a full nitrile glove and more readily available.]

Have a Good Supply Chain Partner

A good supply chain partner can help you navigate the most serious supply chain issues in the cannabis industry.

While this may seem a bit self-serving, given that our company is a supply chain solution provider for the cannabis industry, we have seen the tangible benefits of collaborating with some of the largest cannabis operators in the US.

A good supply chain partner can help you with procurement, distribution, and planning for your cannabis operation. It’s often more cost-effective to consolidate these kinds of activities with a third party rather than to try to manage all the moving parts yourself.

A good supply chain partner will likely be working with multiple cannabis operators, all with similar needs for basic items. Through collective purchasing power, a supply chain partner can help to navigate some of the thorniest supply chain issues in the cannabis industry.

And even when specific items or brands are not available, your partner should be able to recommend alternatives that will help you keep your business chugging along with minimal disruption.

Providers, such as Omega Equipment & Supply have deep relationships with hundreds of industry vendors. And we are constantly on guard for anything that could disrupt the flow of goods to their customers. Being a good supply chain solution for the cannabis industry means being a trusted advisor that helps you to look out for your business.

Conquering Supply Chain Issues in the Cannabis Industry

Like it or not, supply chain issues in the cannabis industry are going to be with us for quite a while. But with some planning and a good partner, you should be able to not only survive these challenges but thrive.

Whether it is providing guidance on product delivery schedules for new builds or recommending alternate products to substitute for items that are currently unavailable, a good supply chain partner can be a key ingredient in your company’s success and profitability.