A Call for Systematic Approach to Sustainability in Cannabis Facility Design

Principal & Co-Founder

Anderson Porter Design

Chair Emeritus of the

NCIA Facility Design Committee

A Long Journey

There is a cultural challenge and call to action needed to achieve Environmental Sustainability within the cannabis industry. Because of stigma and outcast status, cannabis has always been invited to a different set of parties. The parties to which weed is only slowly getting invites to (long overdue) have names with 3 and 4 letter acronyms. ISO, ANSI, ASHRAE, AIA, NFPA, ASABE, DOER, FDA, ASTM, EU-GMP and anything with a .GOV.

The culture shift is bilateral. Utility companies were once thought of as the enemy because they reported customers who were “using too much electricity”. Today they are mandated to assist in energy planning with some indoor cultivators eligible to receive rebates on energy investments.

Many licensed Architects and Engineers have not been willing to work on cannabis because of stigma. In 2015 there were engineering firms who turned down requests for proposals citing Government Service Administration contracts or were fearful generally how it would look to their more conservative client base if they took on cannabis work. Many architects deign to design a facility here or there but feel industrial work does not meet the goals of the profession.

Cultivation Facilities are designed for plants not (just) for people. Advancements in CEH have broad implications for food production and drug manufacturing globally. That shift in thinking is slowly making its way through the system. Broadly speaking, cannabis industry denizens (consumers, cultivators, and entrepreneurs), have been told no to most things they’ve proposed in life (smoking behind the gymnasium, growing weed in the basement or borrowing money to fund an industrial scale operation). In the push forward, Architects, Engineers, Legislators, Regulators, equipment manufactures, and related industries are scrambling to coalesce disparate laws and regulations to aid and direct the growth. So we’re in a hot mess with aggressive lenders pushing for profit, a group who have grown up fighting the system, a system that is slow to change, and a lingering stigma. Bring it on!

The Intersection of Two Worlds

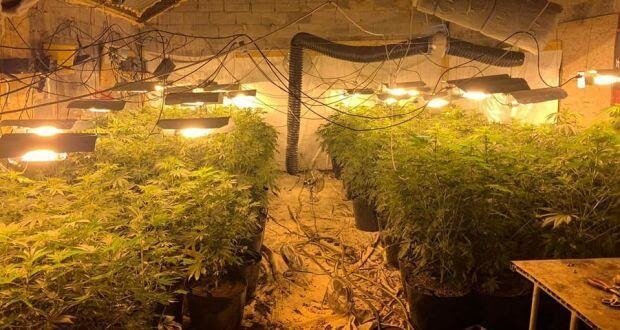

I recall an early design meeting I was in with the consulting grower to our first cannabis customer in 2015. We sat in a suburban Boston office park conference room and we asked the grower what the ideal and target environmental conditions and design criteria for flower rooms on this new job were going to be? The consultant said: “I can grow weed anywhere; I can grow right here in this room.”

Photograph: Garda Síochána/Facebook

And it turns out he had, as many have, grown in rented houses and garages.

At that time there was little communication between the two worlds, let alone a path from one to the other. From the unregulated legacy world to the world of regulations and standards.

Photograph: Fluence Bioengineering

Standards Point the Way to Reliable Sustainability

To advance lasting sustainability, it can be broken down into four steps:

Develop a balanced Program. (CapEx and OpEx)

Build the facility according to the program.

Measure and analyze the results. (Cx and POE, BPE)

Learn from findings and improve where possible.

This aligns with PDCA (Plan-Do-Check-Act), also known as the Deming Cycle of Continuous Improvement. Facility Program (Plan) – Facility Design and Construction (Do) – Study and analyze (Check) – repeat, improve from lessons learned (Act)

W. Edwards Deming – cycle of continuous improvement

An analogy from basic science is: Make a prediction or hypothesis, run the experiment, measure the results, report the results and test for compliance and or certification. PDCA methodology forms the basis for cGMP within FDA, it parallels and compliments ISO 9001 for Total Quality Management, and is the methodological framework for implementation of ISO 50001 - the International Standard for Energy Management Systems.

If adopted and followed here in the US and globally PDCA and the cycle of continuous improvement will allow facilities to achieve sustainable results.

PLAN

In the Architecture Engineering and Construction Industries (AEC) first stage of the cycle is PLAN.

This can go by various names; URS (User Requirements & Specifications), Programming, Planning, or Design Criteria.

The Program is the term commonly used in facility design and operations management. It includes criteria shaped by standards, required by codes and regulations, and targets to meet Owner’s Project Requirements.

Elements of a Program

1.) Owner’s Project Requirements, Design Criteria:

Facilities are designed and built based on an Owner’s Program. If an Owner does not have a Program, one must be developed together with the assembled team. This includes The Architect of Record (AOR), Horticulture Process Engineer, Manufacturing Process Engineer, and other hired Subject Matter Experts (SME).

For Owners and Operators with facilities already in operation, the same team is typically deployed but the information, data and programmatic elements are more readily measured. From ongoing operations historical data can be collected, these are also known as Key Performance Indicators (KPIs):

Grams/sf - biomass produced/canopy square feet / per harvest cycle

Grams/kWh - how much energy was consumed to produce saleable product

Capacity Utilization - the potential output vs actual

Cycle Time Ratio - operational efficiencies

KPIs should be defined for each of the functional areas of the facility. Horticulture, Manufacturing, Packaging, Business Operations and Retail.

Benchmarking - is the measurement of a facility’s performance against an industry standard.

According to the American Society of Quality (ASQ): Benchmarking is defined as the process of measuring products, services, and processes against those of organizations known to be leaders in one or more aspects of their operations. Benchmarking provides necessary insights to help you understand how your organization compares with similar organizations, even if they are in a different business or have a different group of customers.

Resource Innovation Institute (RII) has developed the current goto cannabis/hemp specific energy benchmarking tool - Cannabis PowerScore Resource Benchmarking Tool - Energy, Water, Waste.

PowerScore is an online software suite of tools including a survey, facility-level performance benchmarks, dashboards and reports. Confidential facility PowerScore surveys and secure data transfer create performance benchmark reports empowering cultivators to understand, track and improve their energy and resource efficiency.

International Facilities Management Association (IFMA) has a research arm which promotes benchmarking standards: (none of these yet are cannabis related) Benchmarking - IFMA Research IFMA Research.

2.) Laws and Codes:

Local Municipalities will regulate odor emissions (volatile organic compounds - VOCs), noise (from chillers and cooling towers) traffic, stormwater management, land use, zoning, and importantly fire/life safety and code enforcement.

State Regulations are typically based on industry Standards. These fall into categories; energy consumption, horticulture lighting power density ( horticulture lighting measured in PPE photosynthetic photon efficiency/ sq ft of canopy), water consumption regs, water discharge regs, solid waste and green waste management.

Federal – cGMP, Food Safety, HACCP (Hazard Analysis and Critical Control points) and Sanitary Design.

3.) Standards:

Standards organizations: ASHRE, NFPA, ASTM, UL, ISO,

NFPA – Cannabis Fire Safety Resources: Cannabis Fire Safety Resources

ASHRE 189.1 - https://www.ashrae.org/technical-resources/bookstore/standard-189-1

Code Orgs: I-codes (IBC, IECC, IEBC, etc)

Industry groups:

NCIA - NCIA | Advocating for the Responsible Cannabis Industry

Resource Innovation Institute (RII) - Best Practices for Cannabis Cultivation Operations

RII has published two ‘best practice’ guides for HVACD and LED Lighting Bloggers (myriad) - Cannabis Cultivation and Science Podcast – KIS Organics

The Cannabis Conservancy - The Cannabis Conservancy - the CANNABIS CONSERVANCY

USGBC - https://www.usgbc.org/ - LEED Reference Guide for Green Building Design and Construction with Global ACPs | US Green Building Council

DO

In the PDCA cycle ‘Do’ is the Perform phase. These may be small scale process improvements conducted within a department, as an experiment or a prototype. But in AEC terms for cannabis facilities this is the Design and Construction phase.

Once the Program is established design begins. The Architect of Record (AOR) and Engineer of Record (EOR) and the entire team will rely on and refer to the elements within the Program; OPR and Design Criteria throughout the design phase. Others rely on it as well, including sub-consultants designing specialty systems such as solvent extraction, fertigation systems, energy modeling, etc..

Continuous Improvement with the Design Phase - PDCA with Small Loops and Iterations

The “DO” phase is made up of Design and Construction and has steps within it that lead to increased efficiency and sustainability.

Integrated Project Delivery, Basis Of Design, Peer Review, and Design Phase Commissioning

Integrated Project Delivery (IPD)

Tight coordination between Owner, Design Team and Construction Team is essential to eliminate waste, overproduction, miss-direction and lost time. Integrated Project Delivery is a term of art, now widely understood in the AEC industry. Integrated Project Delivery for Construction - IPD.

The Lean Construction Institute is champion of this and other lean core principles, here in the US and globally. Learning | Lean Construction Institute | Project Delivery.

Coordinated Basis of Design (BoD)

Architects, Engineers and Horticulture Process Engineers assist growers and facility operators through the Design process. The Basis of Design is a document produced to translate the elements of the Program into plans and specifications. This shared document is the road map to get from KPIs to the final built facility.

Peer Review through Utility Efficiency Programs

Many Utilities now offer incentives to promote energy savings. The incentives may include subsidies on energy modeling by a 3rd party, a form of peer review, or rebates for selecting LED lights or other HVACD strategies which push a facility to perform above code minimum.

Design Phase Commissioning

Design phase Commissioning (Cx) will also rely on and refer to the Program, Design Criteria, OPR and BoD when reviewing drawings. Design phase Commissioning may occur as early as 60% of drawing completion or at 90% and again at Issue For Construction (IFC). Design phase Cx is 3rd party confirmation (another form of Peer Review) that the design intent represented in the drawings reflects the Program.

Lean Construction

Obviously the largest expense in the CapEx budget is the construction phase. The value of IPD and Lean Construction is to eliminate waste in this phase.

Construction industry studies have shown 50% or more of the effort required to deliver a built environment is non-value added effort, or waste in the eyes of the customer (CII, 2004). The effectiveness of a labor hour has not improved in the last 50 years, while other industries have seen significant advancements (Teicholz, 2004). Demographics and labor shifts have significantly reduced the construction industry’s labor availability, and the relative cost increases of the built environment are not satisfying the business needs of many of its customers. https://www.leanconstruction.org/

CHECK

This is the Monitor Phase. Time and resources must be set aside to measure and analyze the results. Was the program followed, is it doing what it was designed to do?

If not, why not?

Measure the outputs based on the design KPTs. Ask, Can the equipment operate at design conditions and achieve the targets? There are established presidents for this type of analysis in the facility world – Building Commissioning (Cx) and Post Occupancy Evaluations (POE).

New Construction Commissioning (Cx)

Industry Standards include ASHRAE/ANSI/IES Standard 202 / ASTM standard E2813 - 18 for building enclosures.

Ideally Building Commissioning begins in the design phase as QA/QC over the process. This level of Cx assures ownership that the built facility will perform according to the OPR as defined in the Program.

This is a neutral professional Engineer. It is typically a 3rd party review engineer, not part of the design team, who is contracted directly to the owner. Best practice is to have this group hired early in the design phase prior to construction start to review the full program, Basis of Design and the plans and specifications from each design discipline. They are present and on-site during construction as a 3rd party. Cx provides QA/QC acting independently in addition to and separate from the Builder and Designers.

Further info can be found at: Building Commissioning.

Another type of Cx is Retro-Commissioning.

As an example, a Multi State Operator who is growing by mergers and acquisitions would likely engage Retro-Commissioning to evaluate the performance of the asset they are acquiring, and to compare it to their own standards/requirements. This would be at the level of due-diligence on energy performance but would also go to evaluating the Horticulture and Manufacturing outputs compared to its original design criteria.

Another example is a facility owner may do this after year 1 or year 2 of operations to see if the “dials have shifted” from the initial Basis of Design.

Quick reference for Commissioning and Retro-commissioning: Definition

Post Occupancy Evaluation (POE) / Building Performance Evaluation (BPE)

POEs and BPEs are different from commissioning, mainly because of the audience they are designed to reach and who pays for them.

Public vs Private

Facility Owners typically consider Building Commissioning a cost of ownership. It is a significant risk mitigator between the Facility construction or purchase (CapEx) and the beginning of operations (OpEx) to assure the investment and avoid costly mistakes. Detailed reports and measurements are taken by Cx Agents and used to compare to the Program and BoD. In no case is Cx info displayed for public view.

Performance evaluations over the long term of ownership are often seen as non-critical extras.

There are enlightened operators who understand the value proposition in leading with Environmental, Social, and Governance (ESG) criteria, Utility companies and State Governments are in a position to invest in data collection and leverage performance improvements through incentives or legislation. And such entities are willing to make that info available to the public. A list of the state’s rankings: 50-State Scorecard Reveals States Are Ramping Up Clean Energy.

SMUD for example in Sacramento, CA sponsored studies of indoor horticulture lighting at Amplified Farms in 2017. This was an example of a diagnostic POE or a BPE. Amplified Farms 2017 Indoor Horticulture Lighting Study.

ACT

So with the final installment of Demmings’ cycle, the improvement phase, the cycle begins again. It is a feed-back loop designed to bring the observations and lessons learned from the monitor phase available back to the plan phase.

Resource Benchmarking - Get Your Baseline and Get on the Path to Sustainability

The cannabis industry has a tested platform that producers can use confidentially for free to understand how their facility ranks in terms of energy and water efficiency. Resource Innovation Institute (RII) provides a specialized resource benchmarking platform for cannabis production, Cannabis PowerScore.

PowerScore is an online software suite of tools including a survey, facility-level performance benchmarks, dashboards and reports. Confidential facility PowerScore surveys and secure data transfer create performance benchmark reports empowering cultivators to understand, track and improve their energy and resource efficiency.

PowerScore collects self-reported performance data and cultivation characteristics (such as annual production, monthly water consumption, flowering canopy area, cultivation approach, substrate), and generates a performance benchmark that summarizes up to ten Key Performance Indicators (KPIs) at the facility level. Users benefit by instantly being shown their operation’s ranking relative to the rest of the PowerScore’s database of facility records called the Ranked Data Set.

The PowerScore platform provides useful insights to cultivators of THC and CBD, as well as any other crop grown in a controlled environment. The aggregated PowerScore dataset features the largest collection of analysis on controlled environment agricultural environments. It is cited by governments, utilities and other stakeholders.

In addition to PowerScore, RII also offers peer-reviewed best practices guides and other resources such as it’s Technical Advisory Council. Best Practices for Cannabis Cultivation Operations.

Conclusions. Integrate Technology and Report Data

Our industry must adopt a science-based approach to facility design backed by solid engineering and adopted standards to assure success and sustainability.

Balancing budget and environmental sustainability are critical challenges. The farm/facility with the lowest cost per lb of biomass will make the highest profit in the long term. (facility cost CapEx and labor costs OpEx.)

To foster continuous improvements and continuous learning data must be collected, measured, recorded, and shared.